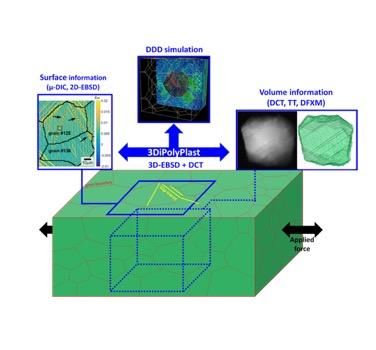

Fig. 1 (top) Experimental reconstruction of the u111 displacement field on a 250 nm Pt NP (bottom) u111 displacement field obtained by energy minimization of a simulated Pt NP (right) εxx, εyy and εzz components of the strain tensor derived from the simulation

Physical properties at small length scale deviate strongly from the bulk counterpart, typically below the micrometer. For instance, mechanical strength increases with reducing size, large residual strain due to processing are present in nanostructures. Thus a better understanding of the physical properties in relationship with the microstructure is needed for nanoscale materials. Because of its good spatial resolution (~ 10 nm) and excellent sensitivity to atomic displacements and local strain [1,2], Bragg coherent diffraction imaging (BCDI) has emerged in the past two decades as a powerful tool to probe the structure and local displacement field inside nanoscale objects [3]. When combined with in situ mechanical loading, BCDI is particularly relevant for the study of defect nucleations in isolated nanoparticles [4] or to investigate intragranular deformation mechanisms in polycrystalline thin films [5].

Nowadays, the length scales that are accessible by BCDI and that can be simulated by Molecular Dynamics (MD) simulation are almost converging. The coupling between the two methods is therefore particularly relevant and allows to get a detailed picture of the deformation mechanisms in nanostructures at the atomic scale. This coupled approach has been used to study the surface relaxation of metallic nanoparticles (Au, Pt). An excellent quantitative agreement is obtained between the component of the displacement field measured experimentally and calculated by energy minimization (Molecular Statics) (Fig. 1). With this approach, the measurement of only one Bragg reflection is required to derive the 3D displacement field and the six independent components of the strain tensor from the simulation [6]. The two techniques can also be combined to identify defect structures nucleated during in situ mechanical loading [4,5] and to interpret the evolution of the strain field in nanoparticle catalysts during gas reaction [7,8]..

[1] Watari, M. et al. Nature Materials 10, 862–866 (2011).

[2] Labat, S. et al. ACS Nano 9, 9210–9216 (2015).

[3] Robinson, I. & Harder, R. Nat Mater 8, 291–298 (2009).

[4] Dupraz, M. et al. Nano Lett. 17(11) (2017).

[5] Cherukara, M. et al. Nat. Comm. 9 (2018).

[6] Dupraz et al. to be submitted (2019)

[7] Kim, D. et al. Nat. Comm. 9, 3422 (2018).

[8] Dupraz, M. et al. in preparation

Speaker: Dr. Maxime Dupraz

Date and Location: Monday 25/11/19, 14h00 LEM meeting room (E2.01.20), Châtillon.