Dr. Antoine GUITTON1,2

1Université de Lorraine – CNRS – Arts et Métiers – LEM3, Metz, France

2LabEx Damas – Université de Lorraine, Metz, France

antoine.guitton@univ-lorraine.fr

www.antoine-guitton.fr

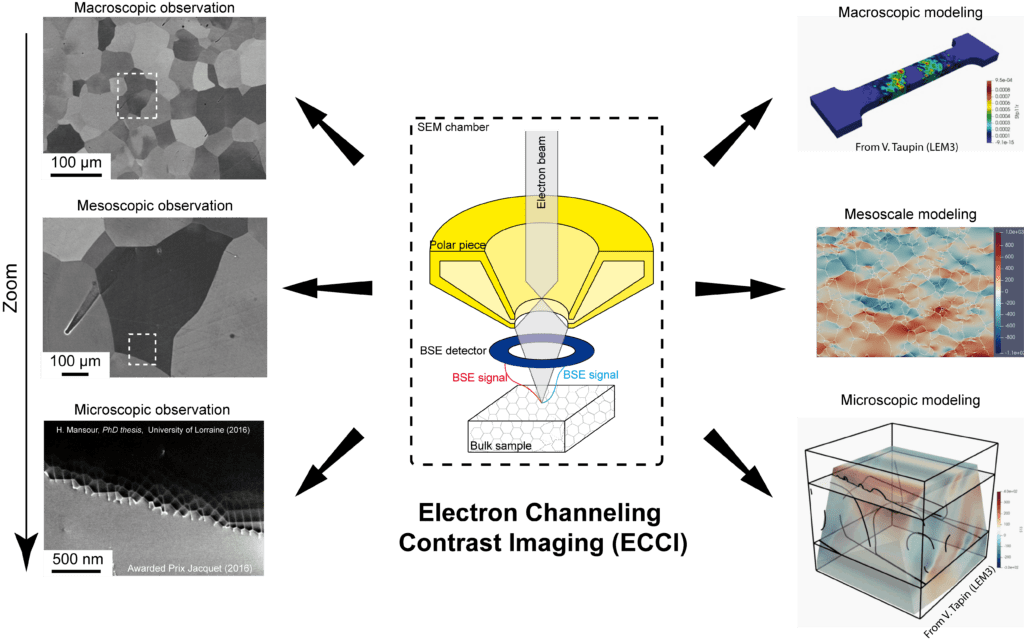

The full potential of ECCI for multiscale comparisons between experiments and simulations.

Although mechanics of materials is aged by more than one century, it still faces many conceptual challenges. One must relate two extreme scales: the sample scale (i.e. Macroscopic) and the scale of fundamental mech- anisms (i.e. Microscopic). In addition, statistics of observations are generally extremely low so that, on one hand the uncertainty is high and on the other hand the representativeness of mechanisms is very questionable.

The Transmission Electron Microscope (TEM) is one of the most well-known techniques for observing and characterizing dislocations in electron transparent thin foils (thickness of ≈ 100nm with a useful field of view of few μm) (1–4). Comprehensive dislocation studies at microscopic scale bring valuable information for extrapolating to the macroscopic mechanical response of materials and they can feed numerical advanced multiscale crystal plasticity models (4). However, fundamental questions on the representativeness of observed phenomenon must be raised, when extrapolating discussions to a millimeter-size specimen.

In this framework, we have successfully combined mechanical testing (nanoindentation and in-situ tensile tests) of bulk specimens with a dislocation-scale characterization technique: Accurate Electron Channeling Contrast Imaging (A-ECCI) (5). A-ECCI is a non-destructive procedure offering the ability to provide, inside a Scanning Electron Microscope (SEM), TEM-like diffraction contrast imaging of sub-surface defects (at a depth of about 100 nm) on centimetric bulk specimen with still unsurpassed resolutions (6).

First, physics of defect contrasts and experimental procedures will be presented (5; 7; 8). Second, the full potentiality of A-ECCI for following the evolution of deformation microstructures will be detailed (9–11). Finally, statistical comparisons between crystal plasticity models and experiences will be highlighted in the framework of a first step towards feature engineering (12–14).

Thursday 27 May 2021 14h00

videoconference at the following link: https://rdv.onera.fr/seminaireLEM

References

[1] G.P. Bei, A. Guitton, A. Joulain, V. Brunet, S. Dubois, L. Thilly, and C. Tromas. Pressure-enforced plasticity in MAX phases: from single grain to polycrystal investigation. Philosophical Magazine, 93(15):1784–1801, may 2013, doi: 10.1080/14786435.2012.755272, hal-hal-01501851.

[2] A. Guitton, A. Joulain, L. Thilly, and C. Tromas. Dislocation analysis of Ti2AlN deformed at room temperature under confining pressure. Philosophical Magazine, 92(36):4536–4546, dec 2012, doi: 10.1080/14786435.2012.715250, hal-03041046.

[3] A. Guitton, A. Joulain, L. Thilly, and C. Tromas. Evidence of dislocation cross-slip in MAX phase deformed at high temperature. Scientific Reports, 4(1):6358, may 2015, doi: https://doi.org/10.1038/srep06358, hal-01503720.

[4] K. Gouriet, P. Carrez, P. Cordier, A. Guitton, A. Joulain, L. Thilly, and C. Tromas. Dislocation modelling in Ti2AlN MAX phase based on the Peierls–Nabarro model. Philosophical Magazine, 95(23):2539–2552, aug 2015, doi: 10.1080/14786435.2015.1066938, hal-01515323.

[5] H. Kriaa, A. Guitton, and N. Maloufi. Fundamental and experimental aspects of diffraction for characterizing dislocations by electron channeling contrast imaging in scanning electron microscope. Scientific Reports, 7(1):9742, aug 2017, hal-02392256.

[6] J. Guyon, H. Mansour, N. Gey, M.A. Crimp, S. Chalal, and N. Maloufi. Sub-micron resolution selected area electron channeling patterns. Ultramicroscopy, 149:34–44, feb 2015, doi: 10.1016/j.ultramic.2014.11.004, hal-01514962.

[7] H. Kriaa, A. Guitton, and N. Maloufi. Modeling dislocation contrasts obtained by Accurate-Electron Channeling Contrast Imaging for characterizing deformation mechanisms in bulk materials. Materials, 12(10):1587, may 2019, doi: 10.3390/ma12101587, hal-02392249.

[8] H. Kriaa, A. Guitton, and N. Maloufi. Modelling Electron Channeling Contrast intensity of stacking fault and twin boundary using crystal thickness effect. Materials, 14(7):1696, mar 2021, doi: 10.3390/ma14071696, hal-03118996.

[9] A. Guitton, H. Kriaa, E. Bouzy, J. Guyon, and N. Maloufi. A dislocation-scale characterization of the evolution of deformation microstructures around nanoindentation imprints in a TiAl alloy. Materials, 11(2):305, feb 2018, doi: 10.3390/ma11020305, hal- 02392252.

[10] M. Ben Haj Slama, N. Maloufi, J. Guyon, S. Bahi, L. Weiss, and A. Guitton. In situ macroscopic tensile testing in SEM and Electron Channeling Contrast Imaging: pencil glide evidenced in a bulk β-Ti21S polycrystal. Materials, 12(15):2479, aug 2019, doi: 10.3390/ma12152479, hal-02392248.

[11] F. Habiyaremye, A. Guitton, F. Sch ̈afer, F. Scholz, M. Schneider, J. Frenzel, G. Laplanche, and N. Maloufi. Plasticity induced by nanoindentation in CrCoNi medium-entropy alloy studied by accurate electron channeling contrast imaging revealing dislocation-low angle grain boundary interactions. Accepted in Materials Science and Engineering: A, 2021, hal-03118990.

[12] M. Ben Haj Slama, V. Taupin, N. Maloufi, K. Venkatraman, A.D. Rollett, R.A. Lebensohn, S. Berbenni, B. Beausir, and A. Guitton. Electron channeling contrast imaging characterization and crystal plasticity modelling of dislocation activity in Ti21S BCC material. Materialia, page 100996, mar, doi: 10.1016/j.mtla.2020.100996, hal-03094460.

[13] K. Venkatraman, M. Ben Haj Slama, V. Taupin, N. Maloufi, and A. Guitton. Tuning critical resolved shear stress ratios for BCC- Titanium Ti21S via an automated data analysis approach. 2021, hal-03119000.

[14] F. Habiyaremye, A. Guitton, X. Lei, T. Richeton, S. Berbenni, G. Laplanche, and N. Maloufi. Influence of the local dislocation density and configuration on the first pop-in load during instrumented nanoindentation. 2021.