Marc Legros, Romain Gauthier, Armin Rajabzadeh, Frédéric Mompiou et Nicolas Combe

CEMES-CNRS, Toulouse

Most crystalline materials around us (metals, alloys, ceramics) are polycrystalline, made of “grains”, separated by “grain boundaries”. These boundaries between domains of different orientation determine certain physical properties and especially their mechanical behavior. For example, we can make a ceramic malleable or on the contrary harden a metal by reducing the size of its crystallites through the famous Hall-Petch law [1,2], established in a phenomenological way for steels 70 years ago. Physically, this relationship can be explained by the obstacle effect that grain boundaries have on dislocations, which are the main vectors of plastic deformation. When grains become nanometric, the plasticity threshold saturates or decreases, which is generally attributed to plastic processes carried by the grain boundaries themselves, such as rotation, intergranular slip and/or migration/shear coupling. These mechanisms are mostly observed in small-grained metals, but rarely quantified experimentally, except in experiments on bicrystals [3]. The Cahn & Mishin (C&M) model [4,5], which popularized the migration-shear coupling, predicts that the coupling factor increases with the disorientation of the joint. In other words, when a joint migrates, it produces more shear the higher its disorientation. The rare measurements made on polycrystals, experimentally more complex to realize, do not seem to attest this trend. And metallic nanocrystals are not known for their deformability.

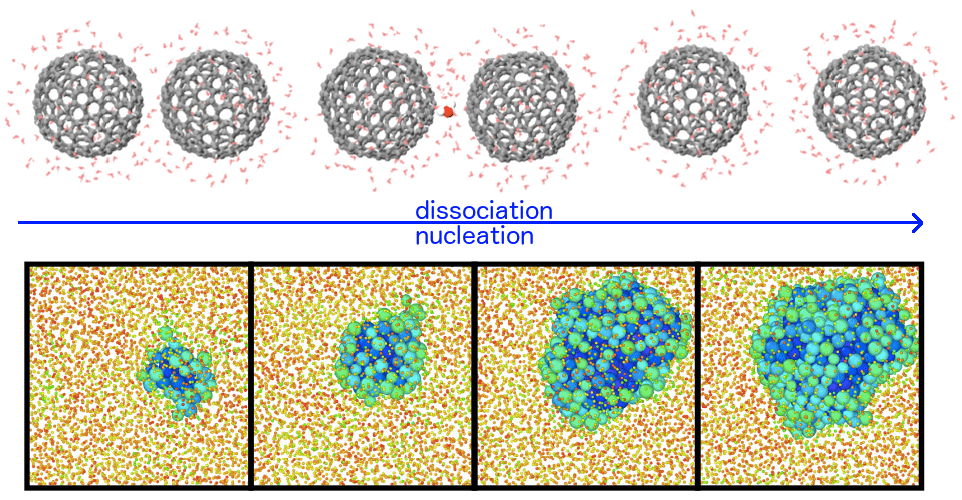

To be sure, we have been studying the deformation mechanisms related to grain boundary migration for the last ten years, both by in situ transmission electron microscopy (TEM), using atomic simulations by molecular dynamics and more recently by atomic force microscopy (AFM), all coupled with crystal orientation mapping techniques. It is thus possible to follow the motion of the identified boundaries and even to statistically quantify the shear produced in ultra-fine-grained aluminum. In the absence of dislocation, this migration-shear coupling is the main driver of plastic deformation [6]. However, this coupling is much weaker than that predicted by the C&M model, which explains the low yield of grain boundary plasticity mechanisms, and thus the low ductility of metallic nanocrystals.

[1] EO Hall. The deformation and ageing of mild steel: III Discussion of results. Proceedings of the Physical Society Section B 1951;64:747–53.

[2] NJ Petch. The cleavage strength of polycrystals: Journal of the Iron and Steel Institute, v. 174. 1953

[3] T Gorkaya, DA Molodov, G Gottstein. Stress-driven migration of symmetrical 〈100〉 tilt grain boundaries in Al bicrystals. Acta Materialia 2009;57:5396–405.

[4] JW Cahn, JE Taylor. A unified approach to motion of grain boundaries, relative tangential translation along grain boundaries, and grain rotation. Acta Materialia 2004;52:4887–98.

[5] JW Cahn, Y Mishin, A Suzuki. Coupling grain boundary motion to shear deformation. Acta Materialia 2006;54:4953–75.

[6] R Gautier, A Rajabzadeh, M Larranaga, N Combe, F Mompiou, M Legros. Shear-coupled migration of grain boundaries: the key missing link in the mechanical behavior of small-grained metals. Comptes Rendus Physique 2021;22:1–16.