Understanding the deformation processes that lead to the failure of polycrystalline structural materials is one of the main challenges in materials science. Significant progress has been made in recent decades, thanks to the development of new experimental characterisation techniques and advanced simulation methods.

However, the localisation of plasticity in slip bands and the propagation of plasticity through a polycrystalline aggregate are not fully understood.

One of the difficulties in modelling the mechanical behaviour of polycrystalline materials is its intrinsically multi-scale nature. Inelastic deformation mechanisms occur at the dislocation scale (dislocation is a crystalline defect ,vector of plastic deformation) that result in the formation of intra-granular microstructures which, in turn, interact with grain boundaries.

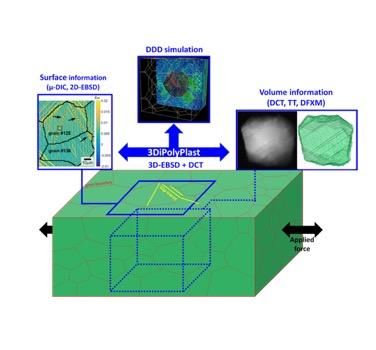

This internship project aims to study the first stages of plastic deformation in policrystalline materials (Cu, Ni) using dislocation dynamics (DD). In particular, the microMegas DD code coupled with a mechanical solver will be used, to correctly handle boundary conditions, to capture the onset of plastic deformation localisation and thus model the interaction between a slip band and grain boundaries.

This mechanism will be studied in a “model” polycrystalline aggregate, and then, if possible, extended to a digital twin of a real polycrystal.

Job: Internship (4-6 months)

Academic level : Master degree

Location: LEM, Châtillon

Expertise: : Solid state physics, Materials Science. Interest in theoretical physics and numerical simulations

Contacts: Benoit Devincre